Content

Direct Definition of a CBB60 Capacitor

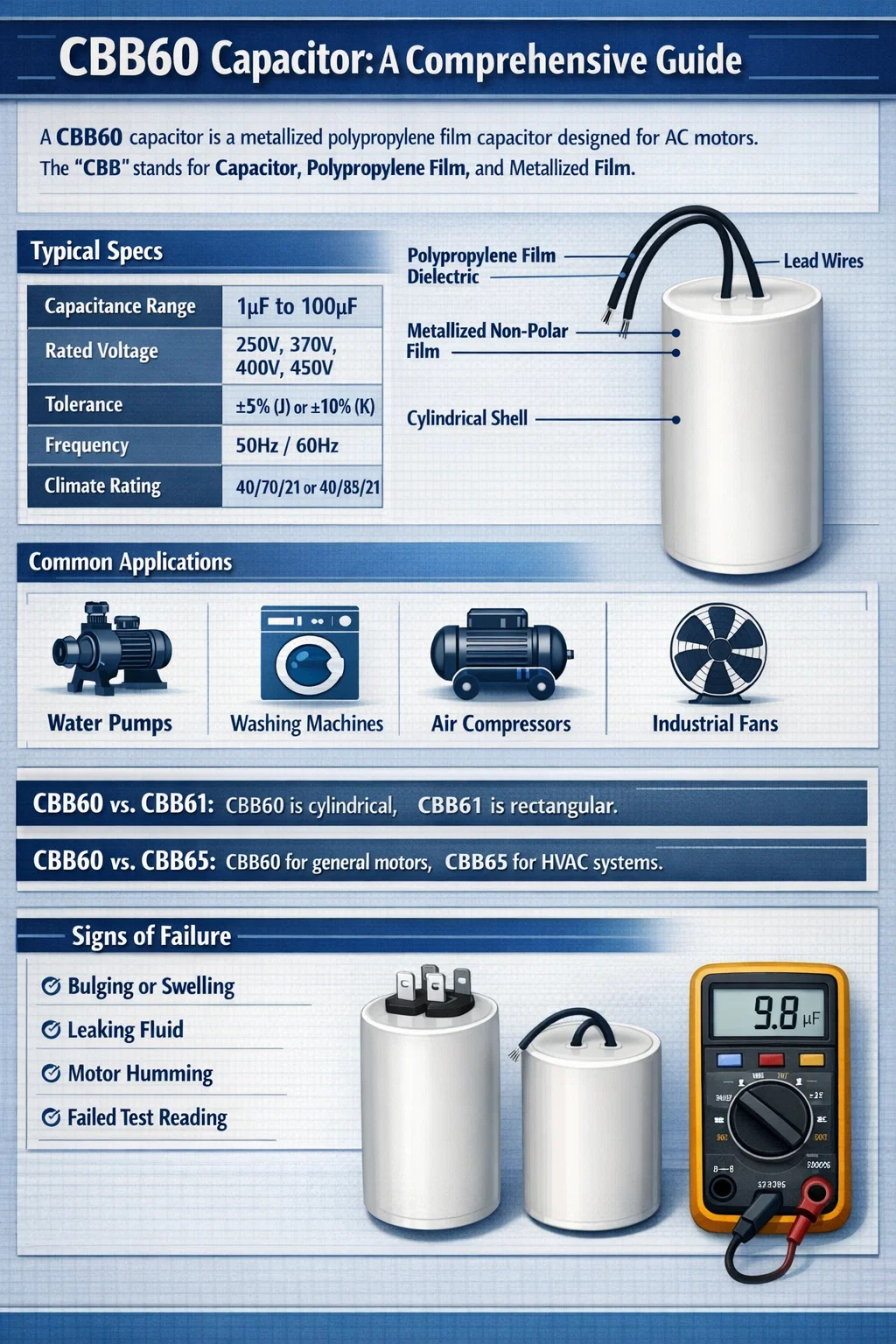

A CBB60 capacitor is a specialized type of metallized polypropylene film capacitor designed primarily for AC motor applications. The designation "CBB" stands for its material composition: "C" for capacitor, "B" for polypropylene film dielectric, and the second "B" for non-polar metallized film. These capacitors are officially classified as run capacitors, meaning they stay in the circuit while the motor is operating to maintain torque and improve efficiency.

Constructed within a cylindrical plastic or aluminum shell, the CBB60 is characterized by its self-healing properties and high insulation resistance. It is most commonly found in household appliances like washing machines, water pumps, and air compressors, typically handling voltages between 250V AC and 450V AC.

Technical Specifications and Construction

The CBB60 utilizes a thin layer of metal (often aluminum or zinc) vacuum-deposited directly onto the surface of a polypropylene film. This design allows the capacitor to be "self-healing," meaning if a dielectric breakdown occurs due to a voltage spike, the thin metallized layer vaporizes around the point of failure, isolating the fault and allowing the capacitor to continue functioning.

Key Performance Parameters

To ensure the longevity of an AC motor, the CBB60 must meet specific industrial standards. Below are the typical technical data points found on a standard CBB60 unit:

| Parameter | Standard Range / Value |

|---|---|

| Capacitance Range | 1µF to 100µF |

| Capacitance Tolerance | ±5% (J) or ±10% (K) |

| Rated Voltage | 250VAC, 370VAC, 400VAC, 450VAC |

| Frequency | 50Hz / 60Hz |

| Climate Category | 40/70/21 or 40/85/21 |

Common Applications of CBB60 Capacitors

The primary intent of a CBB60 capacitor is to assist single-phase AC motors. In these systems, a single phase of power cannot create the rotating magnetic field necessary to start or smoothly run a motor. The capacitor creates a phase shift in the auxiliary winding, simulating a second phase.

You will find CBB60 capacitors utilized in the following equipment:

- Water Pumps: Essential for deep well pumps and garden irrigation systems to maintain constant torque.

- Washing Machines: Used to facilitate the bidirectional rotation of the drum or agitator.

- Air Compressors: Helps the motor overcome the back-pressure of compressed air during start-up.

- Industrial Fans: Provides stable operation for large exhaust and ventilation motors.

Distinguishing CBB60 from Other Capacitors

It is vital for maintenance personnel to distinguish the CBB60 from other common types like the CBB61 or CBB65 to avoid equipment failure.

CBB60 vs. CBB61

While both are polypropylene capacitors, the CBB61 is typically rectangular and used for smaller loads like ceiling fans. The CBB60 is cylindrical and handles the higher current demands of larger appliances like pumps.

CBB60 vs. CBB65

The CBB65 is usually encased in an oval or round aluminum housing and is specifically designed for air conditioning (HVAC) systems. CBB60 capacitors are more versatile and are used in a wider array of general-purpose motor-driven household appliances.

Safety and Maintenance Indicators

Over time, a CBB60 capacitor will degrade due to heat and electrical stress. Identifying a failing unit early can prevent damage to the motor windings, which are significantly more expensive to replace than the capacitor itself.

Watch for these constructive signs of failure:

- Physical Bulging: If the cylindrical top of the CBB60 appears rounded or swollen, the internal pressure has increased due to failure.

- Leaking Fluid: While many CBB60s are "dry" (resin-filled), some contain oil. Any fluid leakage is a sign of a compromised seal.

- Motor Humming: If the motor hums but fails to turn, the CBB60 has likely lost its capacitance (µF) value and can no longer provide the necessary phase shift.

- Testing: A healthy CBB60 should read within ±5% of its rated microfarad (µF) value when tested with a multimeter.

简体中文

简体中文 English

English Español

Español عربى

عربى

+86-13600614158

+86-13600614158

+86-0574-63223385

+86-0574-63223385 Zonghan Street,Cixi City,Zhejiang Province,China.

Zonghan Street,Cixi City,Zhejiang Province,China.