Industry Knowledge Development

The CBB60 capacitor is a type of motor run capacitor commonly used in electric motors for various applications. It is designed to provide a phase shift and voltage boost to the motor's auxiliary winding, improving its starting torque and efficiency. The CBB60 capacitor is housed in a plastic case for insulation and protection.

Here are some key features of the

AC CBB60 plastic case electric motors capacitor:

1.Construction: The capacitor is enclosed in a plastic case, which provides electrical insulation and protects the internal components from environmental factors like moisture and dust.

2.Dielectric Material: The CBB60 capacitor typically uses a metallized polypropylene film as the dielectric material. This material offers high insulation resistance and low energy loss, making it suitable for motor applications.

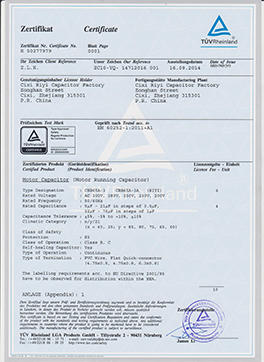

3.Capacitance Value: The capacitance value of a CBB60 capacitor can vary depending on the motor's requirements. Capacitance values are typically measured in microfarads (μF) and can range from a few microfarads to several tens of microfarads.

4.Voltage Rating: CBB60 capacitors are available in different voltage ratings to match the voltage requirements of the motor. Common voltage ratings include 250VAC and 450VAC.

5.Terminal Configuration: The capacitor has two wire terminals or pins for easy connection to the motor's wiring. These terminals are usually made of metal for good electrical conductivity.

6.Mounting Options: CBB60 capacitors often come with mounting brackets or studs, allowing them to be securely mounted within the motor or on an adjacent surface.

When judging the quality of an AC CBB60 plastic case electric motor capacitor, you can consider several factors. Here are some key aspects to assess:

1.Capacitance rating: Check if the capacitor has the correct capacitance rating as specified for your motor. The capacitance is measured in microfarads (μF). Ensure that it matches the requirements of your motor to ensure optimal performance.

2.Voltage rating: Verify that the capacitor has the appropriate voltage rating for your motor. Exceeding the voltage rating can lead to failure or even safety hazards. Make sure the capacitor is rated for the voltage your motor operates at.

3.Build quality: Evaluate the construction and build quality of the capacitor. Look for sturdy and durable materials, such as high-quality plastic casing, reliable terminal connections, and proper insulation. A well-constructed capacitor is more likely to have a longer lifespan.

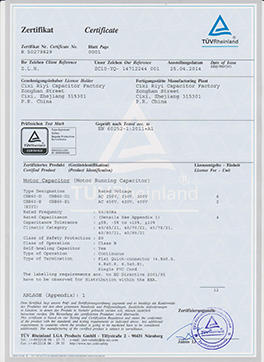

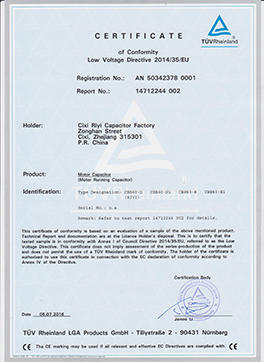

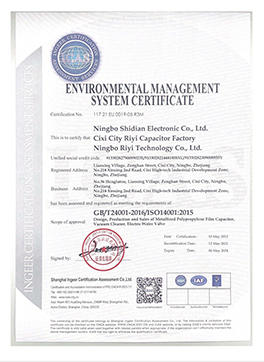

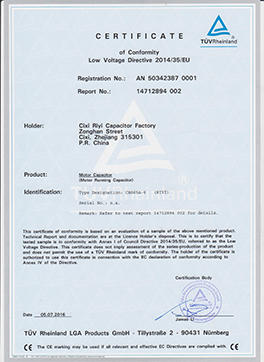

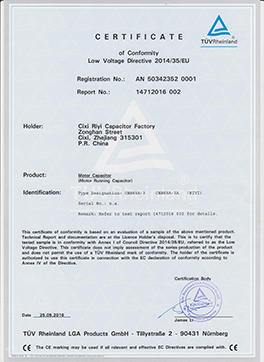

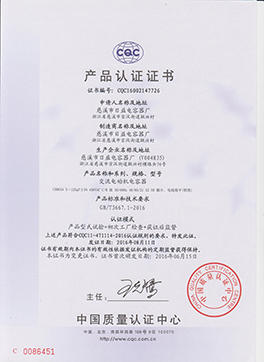

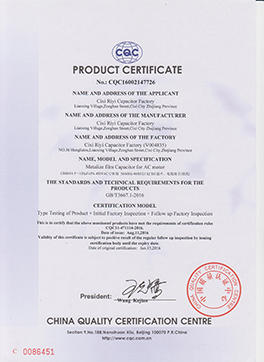

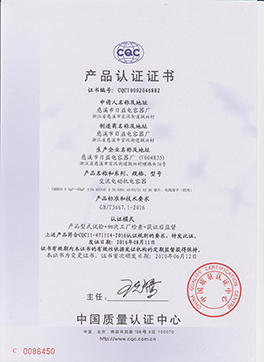

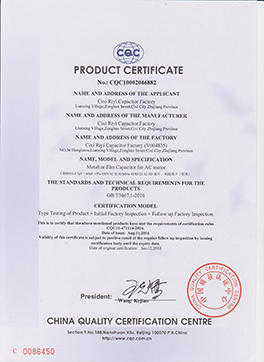

4.Safety certifications: Check for safety certifications like UL (Underwriters Laboratories) or CSA (Canadian Standards Association) marks. These certifications indicate that the capacitor has undergone testing to meet specific safety standards.

5.Manufacturer reputation: Consider the reputation of the manufacturer or brand. Look for well-established companies known for producing reliable electrical components. Read reviews or seek recommendations from trusted sources to gauge the manufacturer's track record.

6.Operating temperature range: Ensure that the capacitor is suitable for the expected operating temperature range of your motor. Capacitors designed for high-temperature environments are generally more durable and reliable.

7.Service life expectancy: While it may be challenging to determine the exact lifespan of a capacitor, manufacturers often provide an estimated service life. Look for capacitors with longer life expectancies, as they tend to be more reliable and durable.

8.Price comparison: While price shouldn't be the sole determinant of quality, it can provide some indication. Compare the prices of capacitors from different brands with similar specifications. If a capacitor's price seems too good to be true compared to others, it might be an indication of lower quality.

Remember that it is always beneficial to consult with a qualified electrician or professional familiar with motor capacitors to ensure you choose the right one for your specific motor application.