Industry Knowledge Development

The AC CBB60 capacitor is a type of motor run capacitor commonly used in water pumps. It is designed to provide a phase shift in the motor windings, which helps improve the motor's efficiency and power factor. The CBB60 capacitor is specifically designed for use with AC (alternating current) motors, including single-phase motors used in water pumps.

Here are a few key features of the CBB60 capacitor:

1.Capacitance: The capacitance rating of the CBB60 capacitor can vary depending on the specific application and motor requirements. It is typically expressed in microfarads (μF) and can range from a few microfarads to several hundred microfarads.

2.Voltage Rating: The capacitor is designed to operate within a specific voltage range, usually ranging from 250V to 450V AC. It is important to choose a capacitor with a voltage rating that matches or exceeds the voltage requirements of the motor to ensure proper functioning and safety.

3.Construction: The CBB60 capacitor is usually cylindrical in shape and enclosed in a plastic or metal casing. It is filled with a dielectric material that provides the necessary electrical insulation and capacitance.

4.Mounting: These capacitors often come with mounting studs or terminals for easy installation in the electrical circuit. They are designed to be mounted directly on the motor or connected to the motor terminals using wires or clips.

When choosing the right

AC CBB60 water pump capacitor, there are a few key factors to consider. Here's a step-by-step guide to help you make the right choice:

1.Capacitance Rating: The capacitance rating is one of the most important factors to consider. Check the specifications of your water pump motor or refer to the manufacturer's documentation to find the recommended capacitance value. The capacitance is typically measured in microfarads (μF).

2.Voltage Rating: The voltage rating of the capacitor should be equal to or higher than the operating voltage of your water pump. It's essential to choose a capacitor that can handle the voltage requirements to ensure safe and reliable operation.

3.Size and Mounting: Consider the physical size and mounting requirements of the capacitor. Ensure that it fits within the available space in your water pump or the capacitor compartment. Also, check if the capacitor has the appropriate mounting options for your specific application.

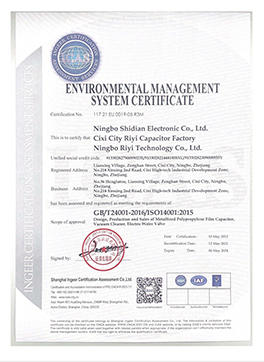

4.Quality and Durability: Look for capacitors from reputable manufacturers or suppliers known for producing high-quality components. A durable capacitor will have a longer lifespan and be less prone to failure.

5.Operating Temperature Range: Verify the operating temperature range of the capacitor and compare it with the environmental conditions in which your water pump operates. Ensure that the capacitor can withstand the temperature extremes without any performance issues.

6.Motor Starting Capability: Some water pump applications require capacitors with specific motor starting capabilities, such as high torque or instant start. Check the motor's requirements to determine if any specific features are needed in the capacitor.

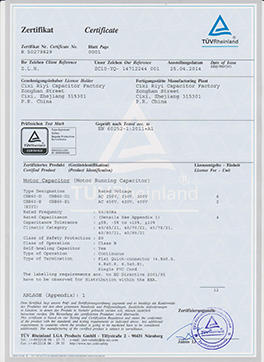

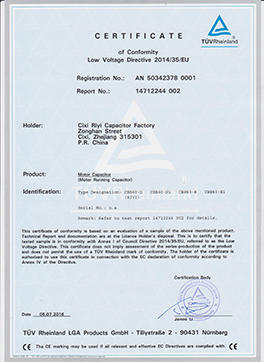

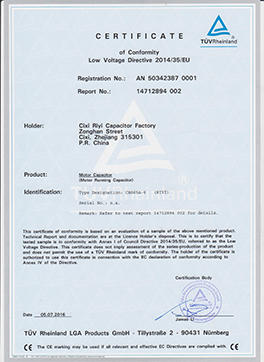

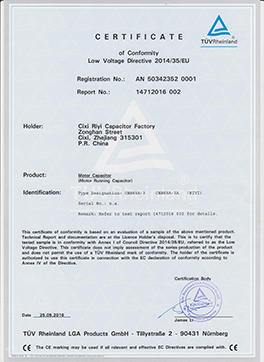

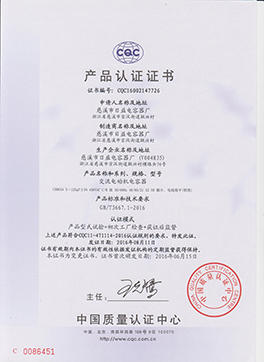

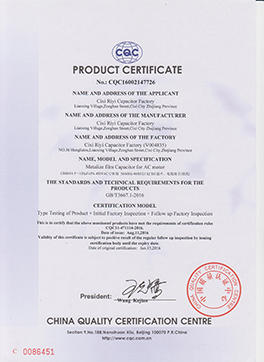

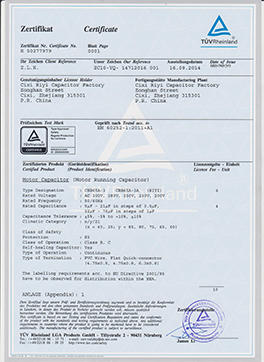

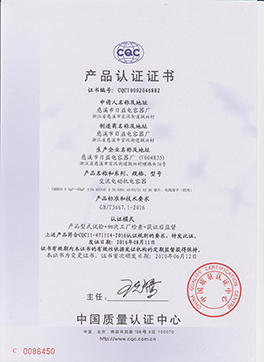

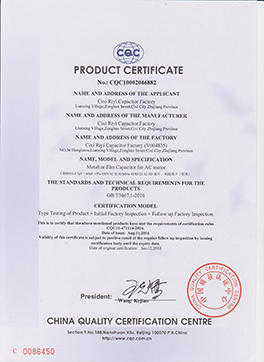

7.Safety Standards and Certifications: Look for capacitors that meet safety standards and certifications applicable to your region. These standards ensure that the capacitor has been tested and approved for safety and reliability.

8.Compatibility: Finally, ensure that the selected capacitor is compatible with your water pump's motor type, such as single-phase or three-phase. Verify the wiring connections and ensure that the capacitor can be properly connected to the motor.