Industry Knowledge Development

The

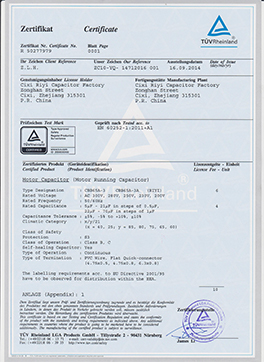

AC CBB61 wire lead motor capacitor is a type of capacitor specifically designed for use in single-phase AC motors, such as ceiling fans. Its purpose is to improve the starting and running efficiency of the motor by providing the necessary reactive power.

Here's a general overview of how the AC CBB61 wire lead motor capacitor works:

1.Capacitance: The capacitor is made up of two conductive plates separated by a dielectric material. In the case of the AC CBB61 capacitor, the dielectric is typically made of metallized polypropylene film. The capacitance value of the capacitor determines its ability to store and release electrical energy.

2.Motor Start: When an AC motor is switched on, it requires an extra boost of power to overcome the inertia and start rotating. The AC CBB61 capacitor is connected in series with the motor's auxiliary winding, which creates a phase shift between the current and voltage. This phase shift creates a rotating magnetic field, which helps in the motor's starting torque.

3.Running Capacitance: Once the motor is running, the AC CBB61 capacitor continues to play a role in improving its efficiency. It provides a phase shift that optimizes the power factor of the motor, reducing the reactive power and improving the motor's overall performance.

4.Rating and Wiring: The AC CBB61 capacitor has a specific voltage and capacitance rating, which should match the requirements of the motor it is used with. It typically has wire leads for easy connection to the motor's wiring terminals.

5.Safety Considerations: Capacitors store electrical energy even when disconnected from the power source. Therefore, it's important to exercise caution when handling capacitors and ensure they are properly discharged before any maintenance or replacement.

To install an AC CBB61 wire lead motor capacitor, follow these steps:

1.Safety first: Make sure the power to the motor or equipment is completely turned off and unplugged to avoid any electrical hazards.

2.Identify the capacitor: Locate the existing capacitor in your motor or equipment. The CBB61 capacitor typically has two or three wires attached to it. It's important to note the wire colors and their corresponding terminals before removing the old capacitor.

3.Discharge the old capacitor (if applicable): If the old capacitor has terminals, use an insulated screwdriver with a short handle to short-circuit the terminals. This will discharge any residual voltage stored in the capacitor. However, if the capacitor is a non-polarized type (without terminals), there's no need to discharge it.

4.Remove the old capacitor: Carefully disconnect the wires from the terminals of the old capacitor. Remember the wire colors and their corresponding terminals for the installation of the new capacitor.

5.Install the new capacitor: Take the new CBB61 capacitor and match the wire colors to their corresponding terminals. The capacitor usually has markings indicating the wire colors and their respective terminals, such as "Fan," "Herm," and "C." Connect the wires securely to their designated terminals.

6.Mount the capacitor: Securely mount the new capacitor in place using zip ties, brackets, or the provided mounting hardware. Ensure it is stable and won't interfere with any moving parts.

7.Double-check the connections: Once the capacitor is securely installed, double-check all the wire connections to ensure they are properly attached and tightened. Make sure there are no loose wires or exposed conductors that could cause electrical issues.

8.Test the installation: After verifying all the connections, you can turn on the power to the motor or equipment. Observe its operation to see if it functions correctly. If there are any unusual noises, vibrations, or issues, turn off the power immediately and recheck your installation.

Note: It's always a good idea to consult the manufacturer's instructions or seek professional assistance if you're unsure about any aspect of the installation process. Electrical work can be dangerous, so taking proper precautions is crucial.